Electronics

Projects involving currents and wires (and other frustrations).

Analog voltage LED bar display

The Oregon Country Fair sees regular participation by students and

faculty from the Physics department at the University of Oregon. We

typically camp at an “ask a scientist” booth inside the “energy park” and

set up from demos allowing us to initiate conversations on

solar/wind/turbine/energy concepts. The Physics Dept. Demo room had some

nifty coils of wire that they’d use to generate e.m.f. by moving a

magnet in and out (or side-to-side) in proximity. They were using

galvanometers to demonstrate both magnitude and sign of the induced

voltage, but it wasn’t flashy enough. So I thought I’d throw together a

bad-LED setup.

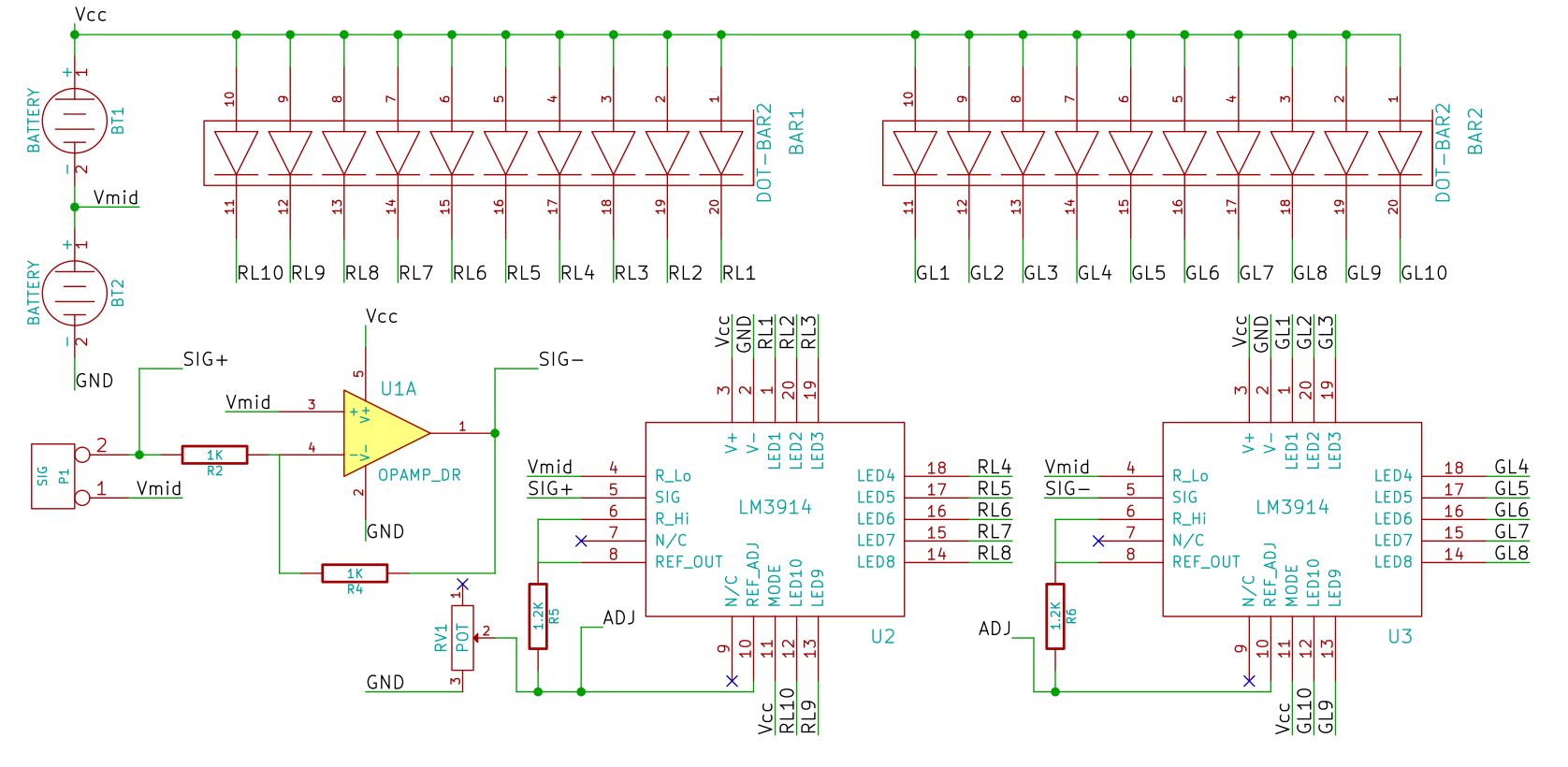

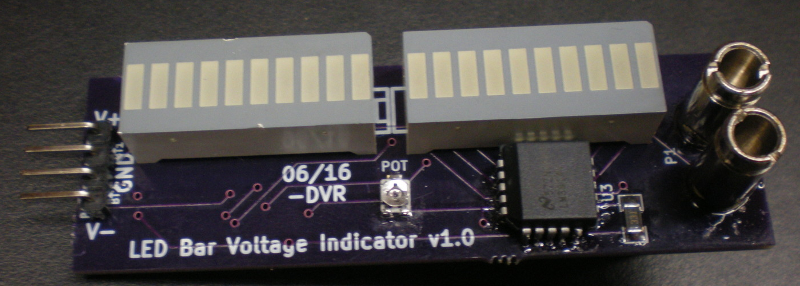

The basic design would use a resistor-ladder divider to generate

voltage-step references, and then use comparators to trigger LEDs. The

Texas Instruments LM3914 driver chip does precisely that. Reference

everything to some midpoint between the terminals of the power supply,

and we get “negative” detection too!

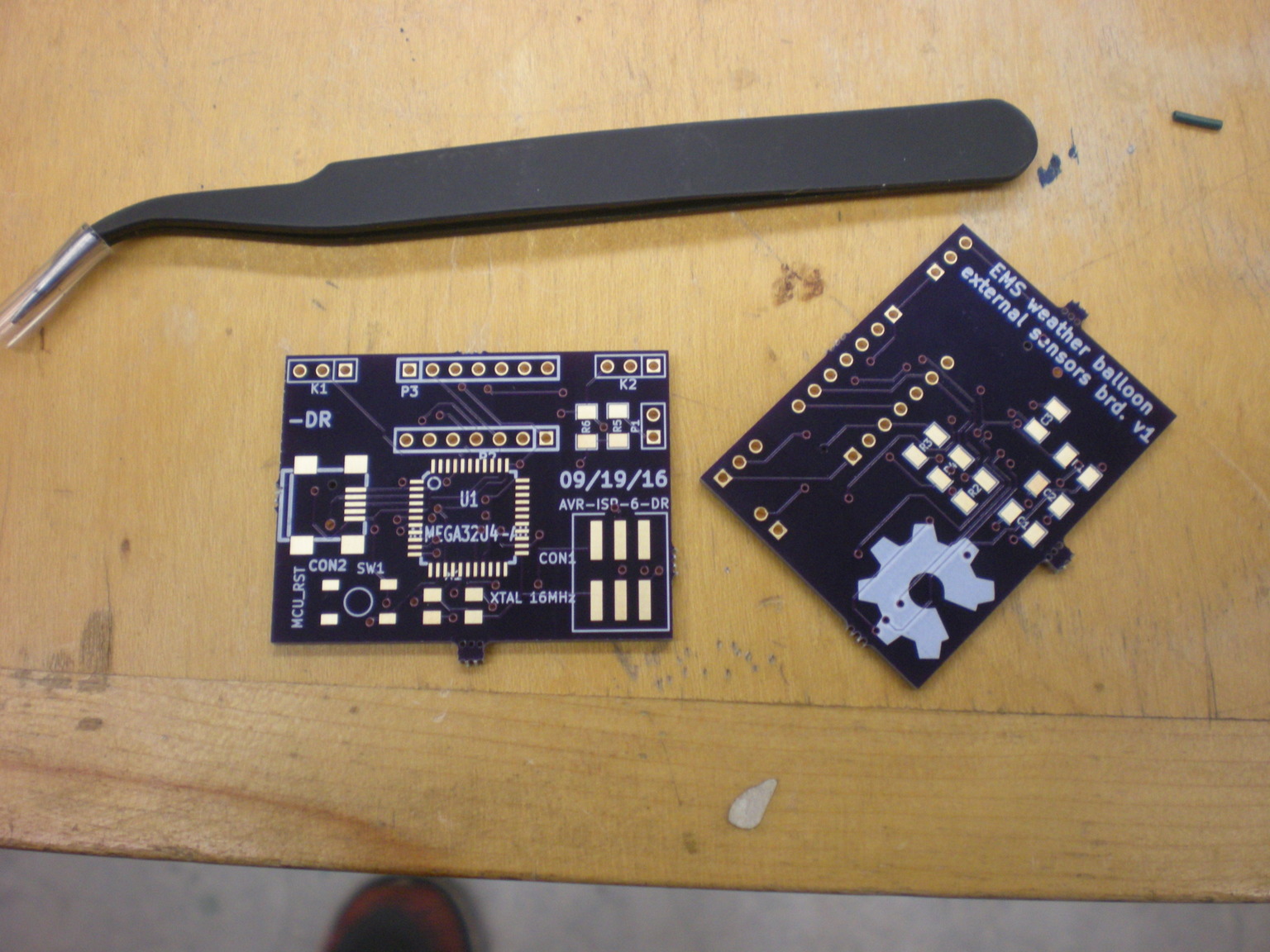

Weather balloon external sensor board

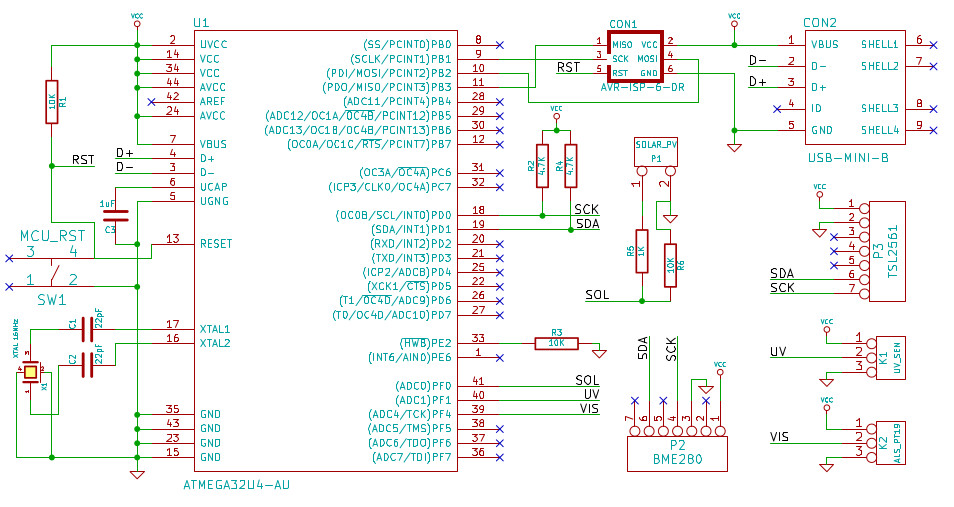

The Weather balloon team at the Eugene Maker Space tasked me with coming

up with a sensor board that would sit outside of the temperature

insulated payload chassis. After some amount of brainstorming, we decided

to put a weather chip, a tiny solar panel, and some kind of spectrometer.

I decided to construct a poor man’s low resolution spectrometer by mixing

together photodiodes with different responsivity peaks. So I went with

Adafruit’s breakout boards for the TSL2561 (reports luminosity,

broadband and IR values), the GUVA-S12SD UV sensor, and the ALS-PT19

natural light sensor chip. Adafruit happens to carry a breakout board for

the BME280 temperature, pressure, and humidity sensor chip as well. The

idea is to solder all of them on a single PCB.

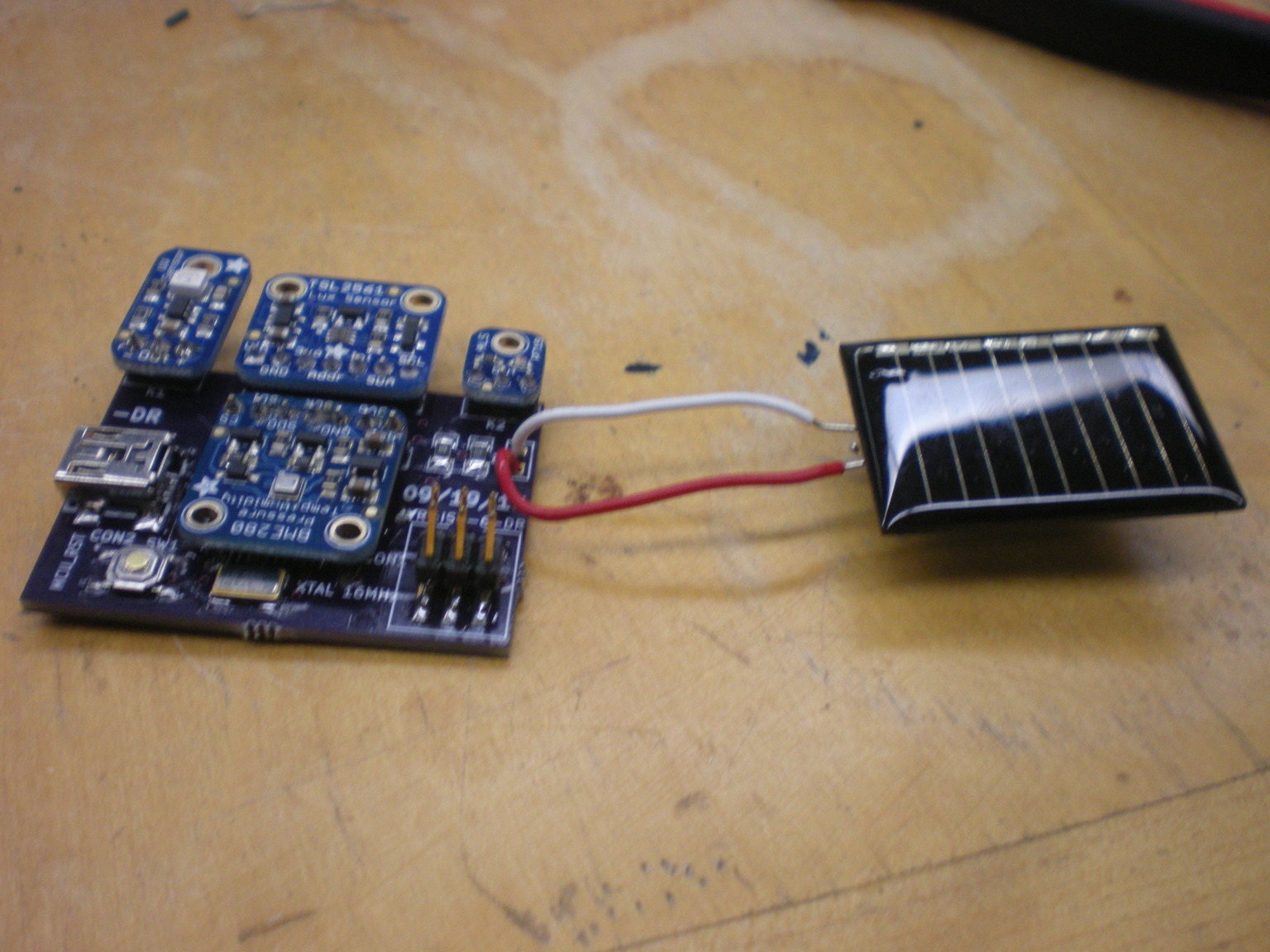

All of them are meant to talk to an ATMEGA32u4 microcontroller either

through I2C bus, or an analog IN pin (we measured the open-circuit

voltage of the solar panel). The microcontroller then periodically (4

times a second) comminucates with a computer inside the payload via a USB

connection. The firmware relies heavily on the Adafruit-Sensor Arduino

libraries. After some calibration, we’d have to think of ways to make it

always face the sun!

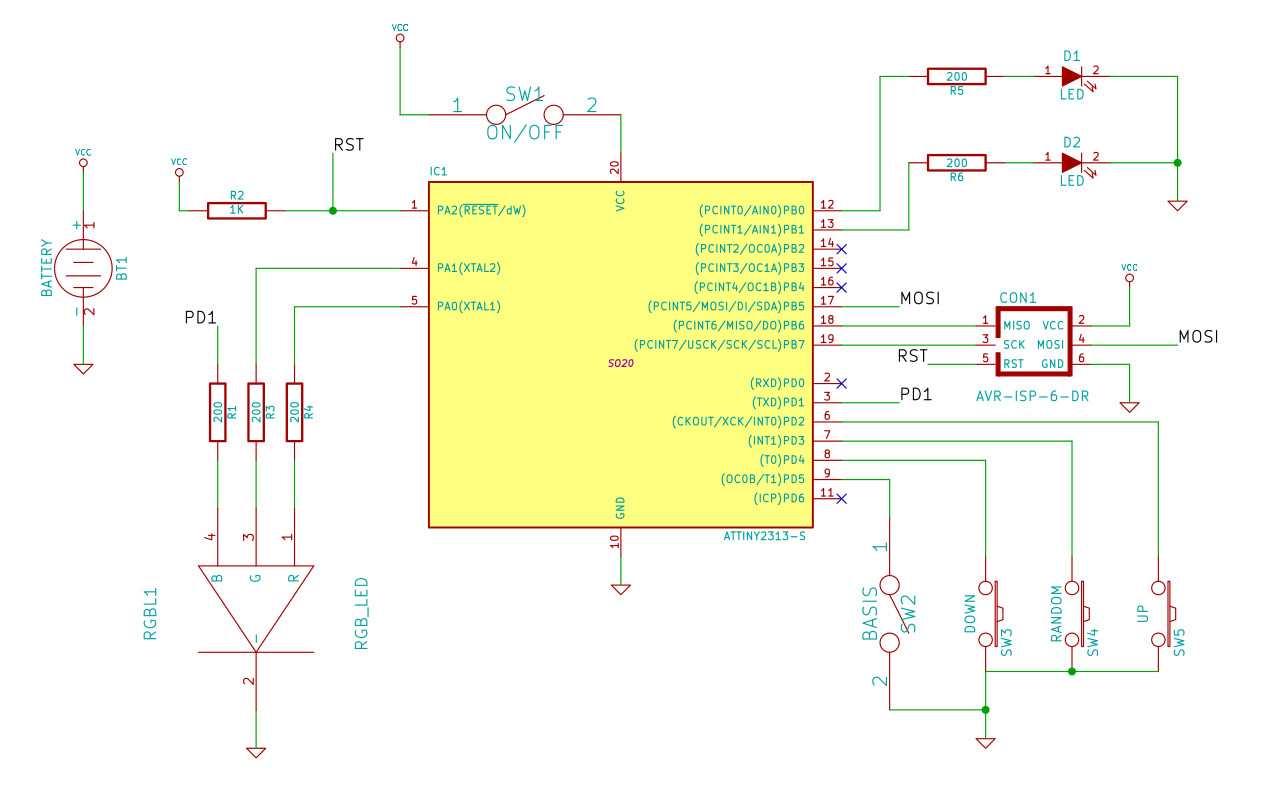

Spin-half

The Science Literacy Program at the University of Oregon often funds

graduate students to help develop and teach new courses. In 2013, my then

advisor Prof. Mike Raymer happened to be creating one called “Quantum

Mechanics for Everyone”, and asked Chris Jackson and me to help design

and TA the course. Naturally, I accepted. At the time, I was just getting

into microcontrollers, and was looking for a project that could use

ATTINY2313 chips. I had to teach Quantum Key Distribution (QKD) to the

class, and hence, had to develop an in-class, hands-on activity that

would help teach non-majors. This, the spin-half board was born.

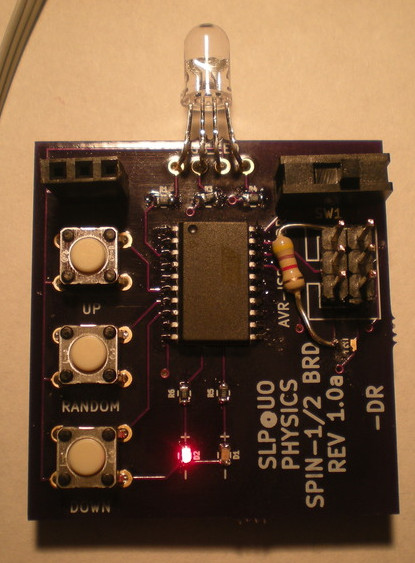

The board has an RGB LED, an SPST switch to change “bases,” and three

push (tactile) buttons. Onboard surface mount LEDs (red and green)

indicate if the current state is the “red/blue” basis, or the

“green/white” basis. It fits in the palm of one’s hand, and is powered

with a coin cell (on the back of the board). This document explains how

it is meant to be used. It essentially allows a student to function as a

spin-half particle, able to respond to external measurements by other

students. They then learn to follow the algorithm illustrated in this

in-class handout document and learn to respect the Born rule. The

activity involved learning to transmit bits from one student to another,

and to study the effects of a third student functioning as an

eavesdropper. The board was programmed using the six ICSP header pins

using code written in avr-gcc. I used a USBtinyISP from Sparkfun to

upload the code using the avrdude interface utility.

Low frequency AM receiver

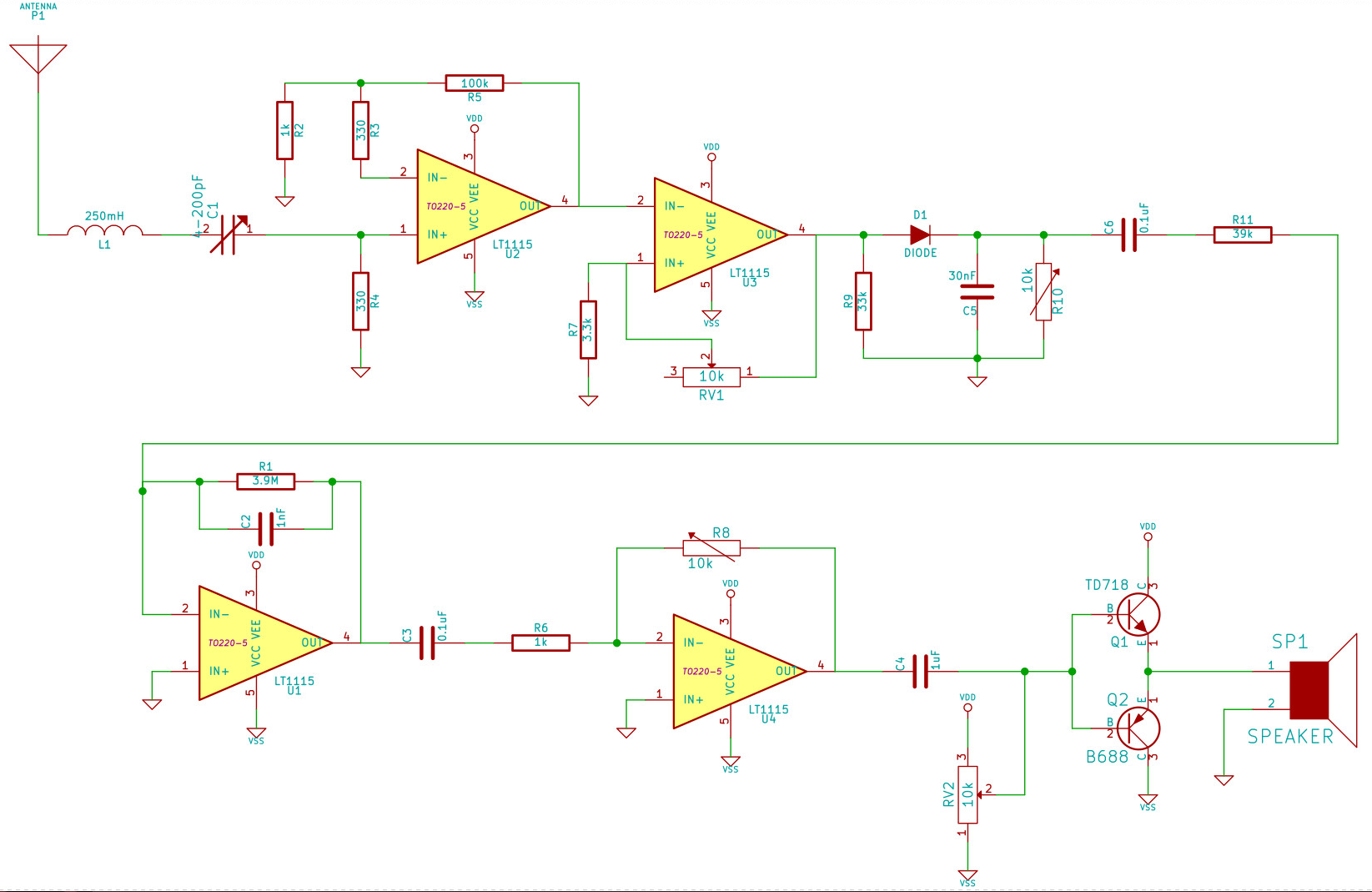

I needed a simple demonstration for AM (amplitude Modulation) based transmission and reception. The primary aim was to demonstrate orthogonality of disjoint frequency bands. And I wanted to do this below 100 kHz, so that a regular oscilloscope could keep up and show some waveforms. DO NOT DO THIS. I was swamped with thermal noise, and just barely got it to work!

The transmitter was using analog multiplier chips. I considered making a Gilbert cell by myself, but couldn’t find matched transistor pairs. Other lessons learnt: Arrange gain amplifiers at the receiver in descending order such that the largest gain is nearer the antenna. This way, noise at every stage doesn’t get amplified at successive stages too much (work this out mathematically. HW assignment!) Also, note that there are low-noise signal (operational) amplifiers that do the voltage translation, and there are power amplifiers, that can actually drive large amounts of current necessary to vibrate a speaker. Use one of those at the end.

Modulating IR diodes for SNR

I’ve attempted to use infrared (IR) emitter-detector pairs in many a project. But unless they are being used as photogates (closely spaced and directly facing each other like IR interrupters), they have always been susceptible to noise. Things got particularly crazy on the SPICE camp Pinball tables, which would rack up points in the presence of incandescent bulbs in the ceiling. The solution is obvious: upshift the information to a higher frequency where there is lesser environmental noise (which is mostly DC). Then use lockin detection, or bandpass filters followed by a demodulation circuit. Sounds complicated, until you realize that commercial remote control technology has been doing this for decades.

The IR receivers come at various IR wavelengths and carrier frequencies. They are astoundingly sensitive, and can pick my signal out from large distances even in sunlight, as long as there is line of sight. People normally advocate using a microcontroller to do both modulation (at the transmission end), and demodulation (at the receiver end), but I’d recommend offloading mundane tasks to dedicated, dump circuits and keeping the microcontroller scheduler free for important tasks.